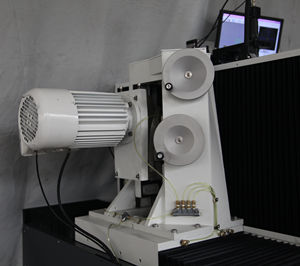

Moresuperhard R & D department is in reference to the Swiss EWAG RS15 machine tool based on independent research and development with independent intellectual property rights of the precision cutting tool machining machine tool (Patent No. ZL 201120162363.7).

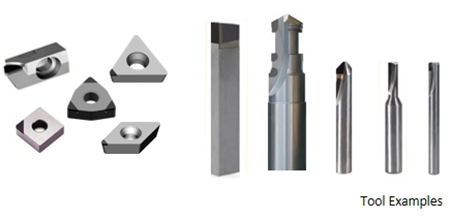

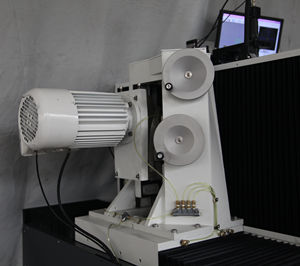

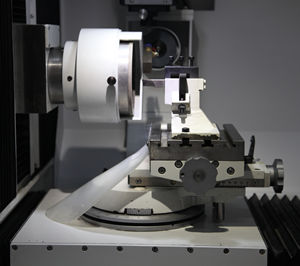

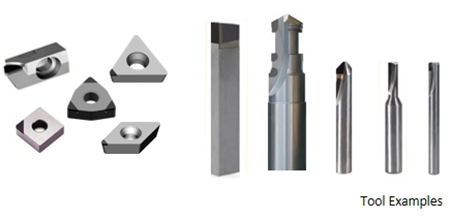

The important parts of this machine tool are selected from the key products of international famous enterprises, and some of the important parts are consistent with the Swiss machine tool selection, which ensures the stability of the machine tool operation, reliability, consistency of machining, as well as the quality of cutting edge and dimensional accuracy of tool machining. The machine tool is mainly used for precision machining of super-hard cutting tools represented by PCD, PCBN, CVD and so on.

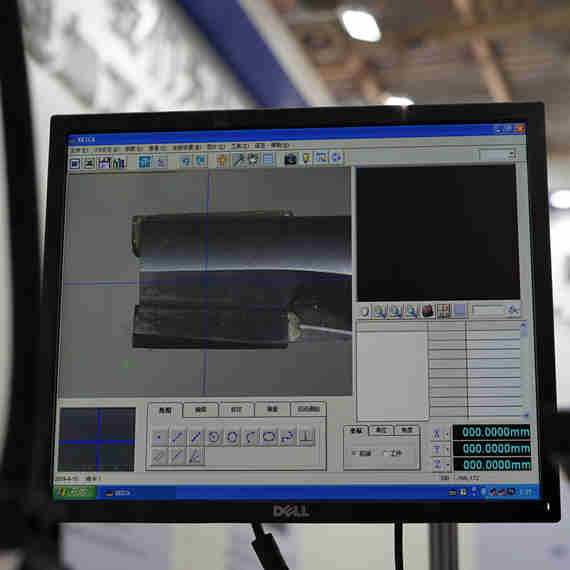

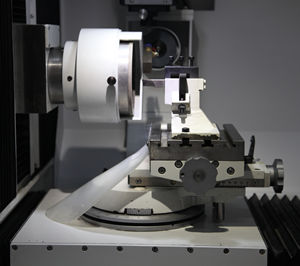

The grinding machine is equipped with constant pressure feeding, fast tool feeding and retracting, automatic vertical axis rotation, on-line dressing of diamond grinding wheel, on-line adjustment of spindle dynamic balance, etc. Used in conjunction with high-precision tool fixtures, the machine tool can complete the high-efficiency machining of precision PCD piston cutter and PCD reamer with a testing precision of 3m or less, and ensure that the surface roughness value of the tool cutting edge is Ra = 0.05m.

At present, BDM-902 machine tool has basically reached the functions of Swiss EWAG RS15 machine tool, and the static testing accuracy of the machine tool has reached the level of FC-500D of Taiwan Yuan Shan Company, which is greatly ahead of the technical level of several domestic super-hard tool grinder manufacturers. Our company is the only high-tech enterprise that can design, produce and assemble high-precision super-hard tool grinding machine in China, and the BDM-902 machine tool is equipped with the functions of automatic rotation of vertical axis, online dressing of diamond grinding wheel, online adjustment of dynamic balance of main spindle, etc. These functions are essential for improving the efficiency of tool machining and guaranteeing the quality of tool cutting edge machining, which also reflect the fact that our company is the only company that can design, produce and assemble high-precision machine tool grinding machine. These functions are indispensable for improving the efficiency of tool machining and ensuring the quality of tool edge machining, which also reflects the leading level of our company in the design of domestic super-hard cutting tool machine tools. Especially, the vertical axis automatic rotation can realize the batch production of tool arc, which is suitable for the batch production of machine-clamped inserts. In addition, the important parts selected for BDM-902 machine tool, including feed guide, moving guide, mechanical spindle, pneumatic components, buffer, etc., are the key products of the international famous enterprises, which is not done by other super-hard tool grinding machines in China.